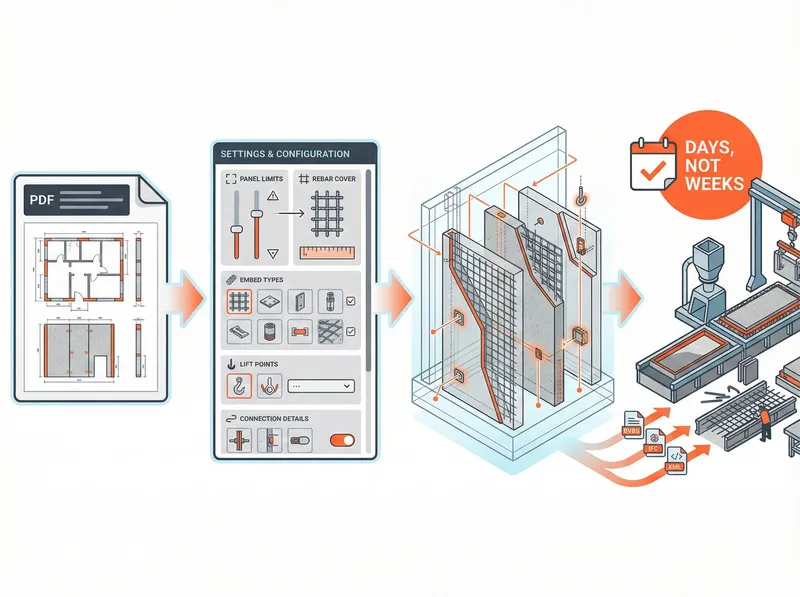

Casting-Ready Models in Days,

Not Weeks.

Generate detailed panel models with rebar placement, embed locations, and lift points—configured to YOUR plant. Skip manual detailing. Start production faster.

The Problem (Your Reality)

Engineers design. You cast. Their drawings give you intent—not production documents. Converting structural designs into YOUR casting documentation requires weeks of manual detailing: rebar placement, embed locations, lift point calculations, connection details. All before your first form is set.

The reality:

Your plant runs on precision. Rebar cages need exact coordinates. Embeds need exact placement. Lift points need exact engineering. Every panel is unique, and every detail matters—because errors in the model become errors in the casting bed. Your detailing team is the bottleneck between winning a project and starting production.

Meanwhile, production can't schedule casting until detailed models exist. Your beds sit waiting while detailing catches up.

How It Works

You Define Your Production Standards

Set your constraints once: panel dimension limits, rebar cover requirements, standard embed types, lift point configurations, connection details. We learn YOUR casting requirements.

You Send the Drawings

Structural PDFs, DWG, or Revit models. We handle the translation.

We Generate Your Digital Twin

Our system creates a detailed LOD 400 model adapted to YOUR production standards. Every panel, every rebar cage, every embed, every lift point—configured to YOUR plant's requirements and tolerances.

Cast Directly

Receive casting-ready models with complete rebar placement, embed coordinates, and lift point details. Your production team gets models ready for form setup and cage fabrication.

Why It's Different

vs. Manual In-House Detailing

Weeks of your team placing rebar, locating embeds, engineering lift points.

Models generated with YOUR production standards from the start. A fraction of the time.

vs. Outsourced Detailing

Send drawings out, wait weeks, receive models that don't match your plant's standards. Revisions add more weeks.

Models configured to YOUR casting requirements from day one. Built for your beds, your forms, your production flow.

vs. Generic BIM Tools

Revit and Tekla weren't designed for precast production. Your rebar standards, your embed libraries, your lift point calculations—none of it is built in.

Models built on YOUR production logic from the start. Every detail configured to how YOUR plant operates.

Ready to Accelerate Your Detailing?

What to Expect

30-minute discovery call. We'll review your production standards and a recent project. Show you how we'd configure models to YOUR plant's requirements.

Why Work With Us

We Built This for Precast Production — We understand precast manufacturing—casting tolerances, rebar placement, embed coordination, lift engineering. We're not here to give you generic BIM. We're here to give you models your production team can cast from.

You Define Your Standards. We Automate Them. — No generic workflow forced on you. You set your constraints—panel limits, rebar cover, embed types, lift configurations. We encode YOUR production standards into every model our software generates. Complete control.

Production Gets Models Ready to Cast — Output adapts to your production workflow—detailed rebar schedules, embed coordinates, lift point engineering. Your team goes from model to form setup without reinterpretation.

Next Steps

Ready to Accelerate Your Detailing?

Looking for faster quantities on new projects? Explore Fast-Track MTO →

Book a Call

30-minute discovery call. We'll review a recent project.

We'll be in touch!

Thank you for your interest. We'll reach out within 24 hours to schedule your call.