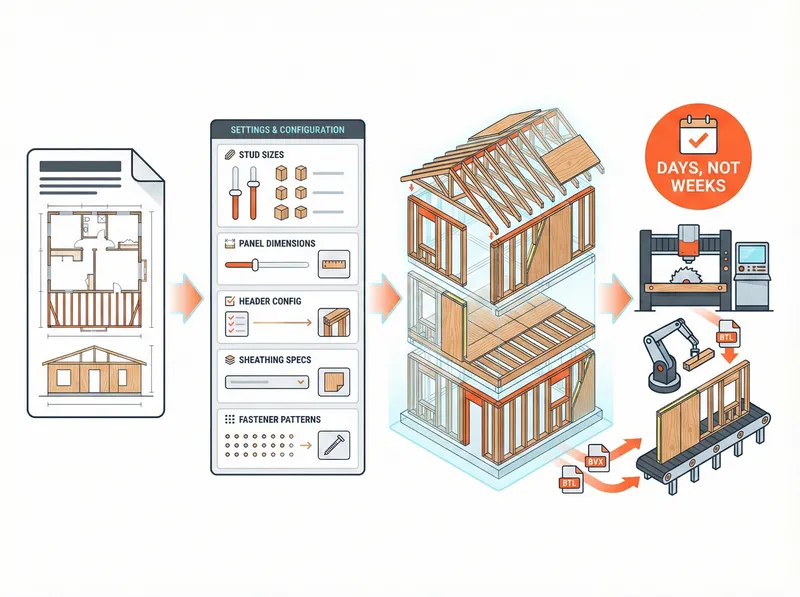

Factory-Ready Models in Days,

Not Weeks.

Generate detailed structural models configured to YOUR manufacturing system. Skip manual detailing. Start fabrication faster.

The Problem (Your Reality)

Architects design. You manufacture. Their drawings don't speak your language—the language of your stud layouts, your panel dimensions, your sheathing patterns, your manufacturing flow. Converting architectural intent into YOUR building system requires weeks of manual work from your team.

The reality:

Your manufacturing system is unique. Your stud sizes, your panel widths, your header configurations, your assembly logic—they live in your team's experience and custom spreadsheets, not in standard design tools. Every project requires your team to reinterpret designs through the lens of YOUR system. It's tedious. It's error-prone. It doesn't scale.

Meanwhile, fabrication can't plan ahead because detailed models don't exist until your team finishes manual detailing. Schedule delays cascade across the entire project.

How It Works

You Define Your Manufacturing System

Set your constraints once: stud sizes, panel dimensions, header configurations, sheathing specifications, fastener patterns. We learn YOUR way of building.

You Send the Drawings

Architectural PDFs, DWG, or Revit models. We handle the translation.

We Generate Your Digital Twin

Our system creates a detailed LOD 400 structural model adapted to YOUR manufacturing logic. Every panel, every stud layout, every detail—configured to YOUR kit of parts and fabrication workflow.

Fabricate Directly

Receive factory-ready models and machine-readable outputs. No reinterpretation. No manual entry. Your digital twin goes straight to CNC programming, BOM generation, and fabrication scheduling.

Why It's Different

vs. Manual In-House Detailing

Weeks of your team translating designs into models aligned with your manufacturing system.

Models generated with YOUR manufacturing logic from the start. A fraction of the time.

vs. Generic Design Tools

Revit, CAD, spreadsheets—designed for architects, not manufacturers. Your kit of parts and assembly rules aren't built in.

Models built on YOUR fabrication logic from the start. Configured to your stud sizes, your panel dimensions, your manufacturing flow.

vs. Fragmented Workflows

Architectural drawings + custom scripts + spreadsheets + manual re-entry = friction and delays at every step.

Single source of truth, configured to YOUR system. From design intent to factory execution, seamlessly.

Ready to Automate Your Detailing?

What to Expect

30-minute discovery call. We'll review your manufacturing system and a recent project. Show you how we'd configure models to YOUR kit of parts and assembly logic.

Why Work With Us

We Built This for Your Reality — We understand timber prefab manufacturing—your stud configurations, your panel systems, your fabrication constraints. Whether you're building panelized walls, floor cassettes, roof assemblies, or something unique to your process, our software adapts to it.

You Define Your Manufacturing Logic. We Automate It. — No generic workflow forced on you. You set your constraints—stud sizes, panel widths, sheathing specs, assembly strategies. We encode YOUR manufacturing system into every model our software generates. Complete control.

Factory Gets Models Ready to Build — Output adapts to your fabrication workflow—machine-readable files that integrate directly with your CNC, scheduling, and planning systems. No guesswork. No delays.

Next Steps

Ready to Automate Your Detailing?

Looking for faster estimation on new bids? Explore Fast-Track MTO →

Book a Call

30-minute discovery call. We'll review a recent project.

We'll be in touch!

Thank you for your interest. We'll reach out within 24 hours to schedule your call.