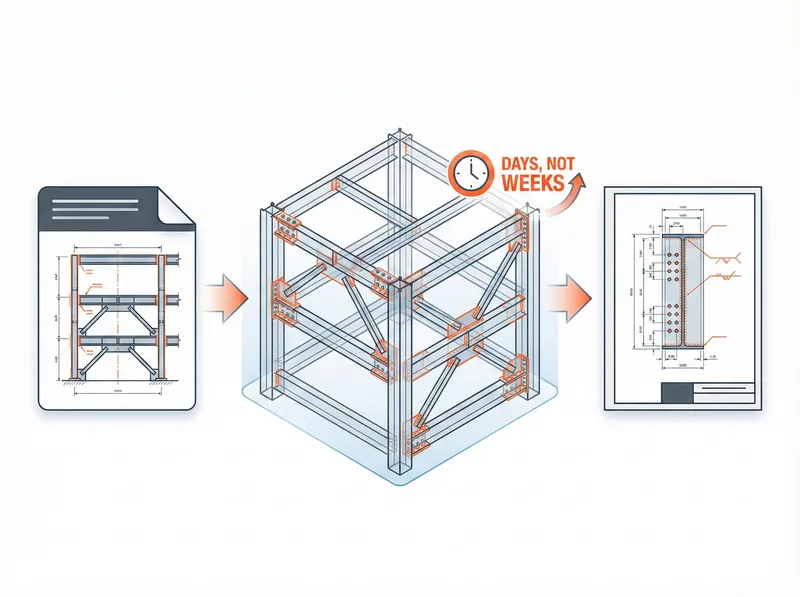

Shop-Ready Models in Days,

Not Weeks.

Generate detailed steel models with connections, bolts, and welds—ready for your detailing team to finish. Skip the modeling grind. Start detailing faster.

The Problem (Your Reality)

Engineers design. You fabricate. Their drawings give you structural intent—not shop-ready documentation. Converting structural designs into models your detailers can work from takes time: modeling members, locating connections, setting up for shop drawing production. All before the real detailing work even starts.

The reality:

Your detailing team's time is valuable. Every hour they spend modeling basic geometry is an hour they're not spending on connection design, clash resolution, and shop drawing production—the work that actually requires their expertise. The modeling grind is a bottleneck, and it repeats on every project.

Meanwhile, the shop can't cut steel until drawings are released. Modeling delays cascade into fabrication delays.

How It Works

You Send the Drawings

Structural PDFs, DWG, or Revit models. We handle the translation.

We Generate Your Base Model

Our system creates a detailed structural model with member geometry, connection locations, and bolt/weld designations—ready for your detailing team to take over.

Your Team Finalizes

Your detailers start with a complete base model. They focus on connection design, fit-up details, and shop drawing production—not basic modeling.

Release to Shop

Finalized models go to shop drawings and CNC. Your fabrication team gets what they need to cut, drill, and weld.

Why It's Different

vs. Starting from Scratch

Your detailers model every beam, every column, every brace before they can start real detailing work.

They start with a complete base model. Geometry is done. Connections are located. They focus on what matters.

vs. Outsourced Modeling

Send drawings out, wait weeks, receive models that need significant rework to match your standards.

Models delivered in days, structured for your detailing workflow. Less rework, faster turnaround.

vs. Relying on Engineer's Model

Engineer's Revit model wasn't built for fabrication. Members are approximated. Connections are schematic. Your team rebuilds it anyway.

Models built with fabrication in mind. Member geometry matches what you'll actually cut. Connection locations are accurate.

Ready to Accelerate Your Detailing?

What to Expect

30-minute discovery call. We'll review a recent project and show you how we'd deliver the base model for your team.

Why Work With Us

We Built This for Fabrication — We understand steel fabrication—the difference between design models and shop models. We're not here to replace your detailers. We're here to let them do real detailing work instead of modeling grind.

Your Detailers Stay in Control — We deliver the base model. Your team finalizes connections, resolves clashes, produces shop drawings. Their expertise, their standards, their output.

Shop Gets Steel Faster — Less time modeling means more time detailing. More time detailing means faster drawing release. Faster release means your shop starts cutting sooner.

Next Steps

Ready to Accelerate Your Detailing?

Looking for faster quantities on new bids? Explore Fast-Track MTO →

Book a Call

30-minute discovery call. We'll review a recent project.

We'll be in touch!

Thank you for your interest. We'll reach out within 24 hours to schedule your call.